Upcut Saws for Industrial Use - A Quick Guide

Upcut Saws

If you work in the manufacturing or construction industries, you may have come across different types of saws used for cutting materials like metal, plastic, and wood. One type of saws that are commonly used in these industries are the upcut miter saws.

In this article, we will take a closer look at what upcut miter saws are, how they work, and their importance in various industries.

What are Upcut Saws?

An industrial upcut saw is a type of saw used for cutting materials like metal, plastic, and wood. They are not to be confused with chop saws or circular saws, which have different cutting mechanisms. Industrial upcut saws are designed with a saw blade that rises from below the material to be cut. This makes them ideal for cutting materials that are too large or too thick for other types of saws.

Upcut saws come in various sizes and designs, depending on the specific needs of the user. They can be manually operated or automated, depending on the size and complexity of the cutting task.

How do an Upcut Saw Work?

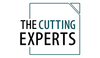

An upcut saw works by lifting the saw blade up from below the material to be cut. The upcut aluminum blade then cuts through the material. The upcut saw blade is then lowered back down to repeat the process for the next cut.

The blade of an upcut saw is typically made from a high-speed steel or carbide material, which allows it to cut through tough materials quickly and efficiently. The saw blade is also designed with teeth that are angled to pull the material up as it cuts, which helps to reduce the risk of chipping and ensures a clean cut.

An upcut saw can be operated manually or with the help of computer numerical control (CNC) technology. CNC upcut saws are automated and can be programmed to make precise cuts, which is particularly useful in industries where accuracy is critical, such as the aerospace and automotive industries.

Benefits of Using an Upcut Saw:

Using an upcut saw offers several benefits compared to other types of saws. Here are some of the advantages:

Better Material Control:

Upcut saws are designed to keep the material stable during the cutting process. The saw's upward motion of the saw blade keeps the material against the fence, providing better control and accuracy.

Cleaner Cuts:

Precise upcut saws produce cleaner cuts with less damage to the material. This is due to the design of the saw blade, which cuts from the bottom to the top. As a result, the saw blade doesn't drag the material or create splinters as it cuts through.

Increased Efficiency:

An industrial upcut saw can cut through materials quickly and efficiently. With its rapid cutting speed, it can cut large volumes of material in a short amount of time, making it ideal for high-volume production, even if they are not motor servo controlled.

Improved Safety:

An upcut saw is designed with safety features to prevent accidents. The blade guard and safety sensors ensure that the operator's hands are away from the saw blade during operation, reducing the risk of injury.

Common Applications of an Upcut Saw:

Upcut saws are used in a wide range of industries due to their ability to cut a variety of materials quickly and accurately. Here are some of the most common upcut saw applications:

Aluminum Fabrication:

An upcut aluminum saw is ideal to cut aluminum extrusions, such as those used in window frames and door frames.

Metalworking:

An upcut saw can be used in the metalworking industry for cutting metal profiles, tubes, and bars.

Woodworking:

Upcut saws are commonly used in the woodworking industry for cutting lumber, plywood, and other wood-based materials.

Plastic and Vinyl:

Upcut saws are used for cutting plastic and vinyl profiles, including PVC and vinyl siding.

Sign-making:

Upcut saws are also used in the sign-making industry for cutting large panels of materials, such as acrylic, foam board, and aluminum composite material (ACM).

Overall, upcut saws are versatile tools that offer several benefits over other types of saws. Their ability to cut quickly, accurately, and safely makes them an essential tool for a wide range of industries.

The Shark Series of Upcut Saws

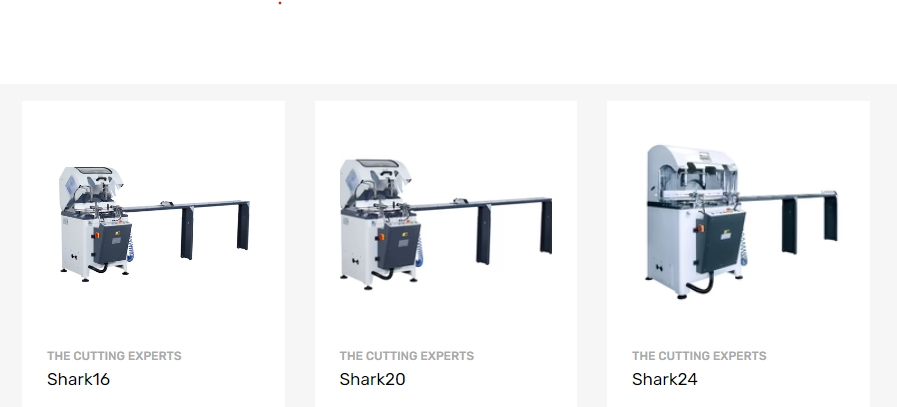

One of the most popular and reliable brands of upcut saws in the market today is the Shark series saw systems. These automatic cutting machines are designed to provide precise and efficient cutting of aluminum, PVC/vinyl, and wood profiles. The Shark series saw systems boasts of several features that make them the preferred choice of many industries.

The Shark series comes in three models - the SHARK16, SHARK20, and SHARK24, with saw blade sizes ranging from 16 inches to 24 inches. All models come with hydro-pneumatic cutting processes that provide a secure and efficient cutting experience.

Additionally, the Shark series offers cutting saw blade speed adjustment based on the profile, which allows for more precise cutting. The single head miter saws can cut at any desired angle between -90° and +45°.

The Shark series also features mobile miter, which increases the cutting capacity, and pneumatic vertical and horizontal clamps, which ensure a secure grip on the material to be cut. The machines are also equipped with cooling systems, which prevent overheating during heavy duty or extended use.

Need CNC-Controlled Cutting? Here’s Who We Trust

While The Cutting Experts specialize in high-quality manual and semi-automatic upcut saws, like the Shark series, we know some operations require more — specifically CNC-controlled cutting. This means the saw can automatically position the blade, control feed rates, and execute pre-programmed cutting cycles without manual adjustments. It’s ideal for high-volume, repeatable production with multiple cut lengths and angles.

For that level of automation, we confidently recommend Gemma Global. Their Kappa CNC Upcut Saw offers precise, programmable control, letting you handle complex jobs efficiently and with minimal operator input. If you need smart automation and consistent output, Gemma delivers machines you can count on.

Conclusion

Upcut saws are versatile and reliable tools that have become essential in many industries. The Shark series of industrial upcut saws offers a range of models that provide precise and efficient cutting of aluminum, PVC/vinyl, and wood profiles.

Whether you are an upcut saw operator in a small shop or a large-scale manufacturer, the Shark series of upcut saws has something to offer for your cutting needs. With their advanced features and dependable performance, the Shark series of upcut saws are a wise investment for any business looking to increase efficiency and productivity.