Industrial Miter Saw: Everything You Need to Know

Industrial Miter Saw: Everything You Need to Know

If you're looking to purchase an industrial miter saw, you have a wide variety of options available. Miter saws (sometimes mistakenly referred to as chop saws) are an indispensable tool for woodworkers and metalworkers alike. They can make quick and precise cuts at a wide range of angles, making them perfect for many different types of projects.

In this article, we'll go over everything you need to know about industrial miter saws. We'll cover the different types of miter saws, their features, and the benefits of using them. We'll also highlight some of the best industrial miter saws on the market today, including those sold by The Cutting Experts.

What is an Industrial Miter Saw?

An industrial miter saw is a type of saw that is used to make precise cuts at different angles. They are commonly used in woodworking and metalworking, and are often seen in carpentry shops, metalworking factories, and construction sites.

Miter saws are designed to make accurate cuts at a variety of angles. They are typically mounted on a stand or a workbench, and have a circular saw blade that is mounted on an arm. The blade can be adjusted to different angles, allowing you to make precise cuts at angles other than 90 degrees.

Types of Miter Saws

There are three main types of miter saws: standard miter saws, compound miter saws, and sliding compound miter saws.

Standard Miter Saws

Standard miter saws are the simplest type of miter saw. Unlike a chop saw, standard miter saws are capable of cutting at various angles, but their blades remain in a fixed vertical position. These saws are great for making simple angled cuts in wood or other materials, and they can be adjusted to make miter cuts at angles other than 90 degrees. Standard miter saws are suitable to cut extruded PVC, extruded aluminum and for basic woodworking projects, such as cutting picture frames or trim work.

Compound Miter Saws

Compound miter saws are more advanced than standard miter saws. They can make cuts at a variety of angles, including beveled cuts. This makes them perfect for cutting crown molding or other types of decorative trim. Compound miter saws can be adjusted to make both miter cuts (cuts made at an angle) and bevel cuts (cuts made at an angle through the thickness of the material).

Sliding Compound Miter Saws

Sliding compound miter saws are the most advanced type of miter saw. They can make all the cuts that compound miter saws can make, but they can also slide back and forth, allowing you to cut larger pieces of material. Sliding compound miter saws are great for making cuts on wide boards or panels. Sliding compound miter saws have become less common in workshops due to increased safety concerns for employees; nowadays, miter upcut saws with larger blades are the preferred choice, as they provide enhanced safety features and reduced risks for workers.

Differences between Miter Saws and Other Types of Saws

Miter saws are often compared to other types of saws, such as a chop saw and circular saw. While they share some similarities, there are key differences that set them apart. Miter saws are designed for precision cutting and are used for making angled cuts in wood, metal, and other materials. Chop saws, on the other hand, are used for cutting through tough materials such as steel, while a circular saw is used for straight cuts.

How do Industrial Miter Saws Work?

Industrial miter saws consist of a blade mounted on a pivoting arm that can be adjusted to make angled cuts. They are also equipped with a fence, which helps guide the material being cut. The blade is powered by a motor that is mounted on the saw head.

Explanation of the cutting process

The cutting process with an industrial miter saw involves securing the material to be cut onto the table of the saw using the clamps provided. The blade is either raised or lowered onto the material, and the angle is adjusted as needed to achieve the desired cut. The accuracy and precision of the cut are attained by carefully aligning the blade's teeth with the desired cutting line, as well as by adjusting the angle of the blade to the appropriate setting for the specific cut required. This ensures that each cut is made with exactitude and a high level of craftsmanship.

Safety considerations

As with any cutting tool, safety is of utmost importance when using an industrial miter saw. Operators should always wear appropriate protective gear, such as eye and ear protection, when using the saw. The blade should also be properly installed and maintained to prevent accidents.

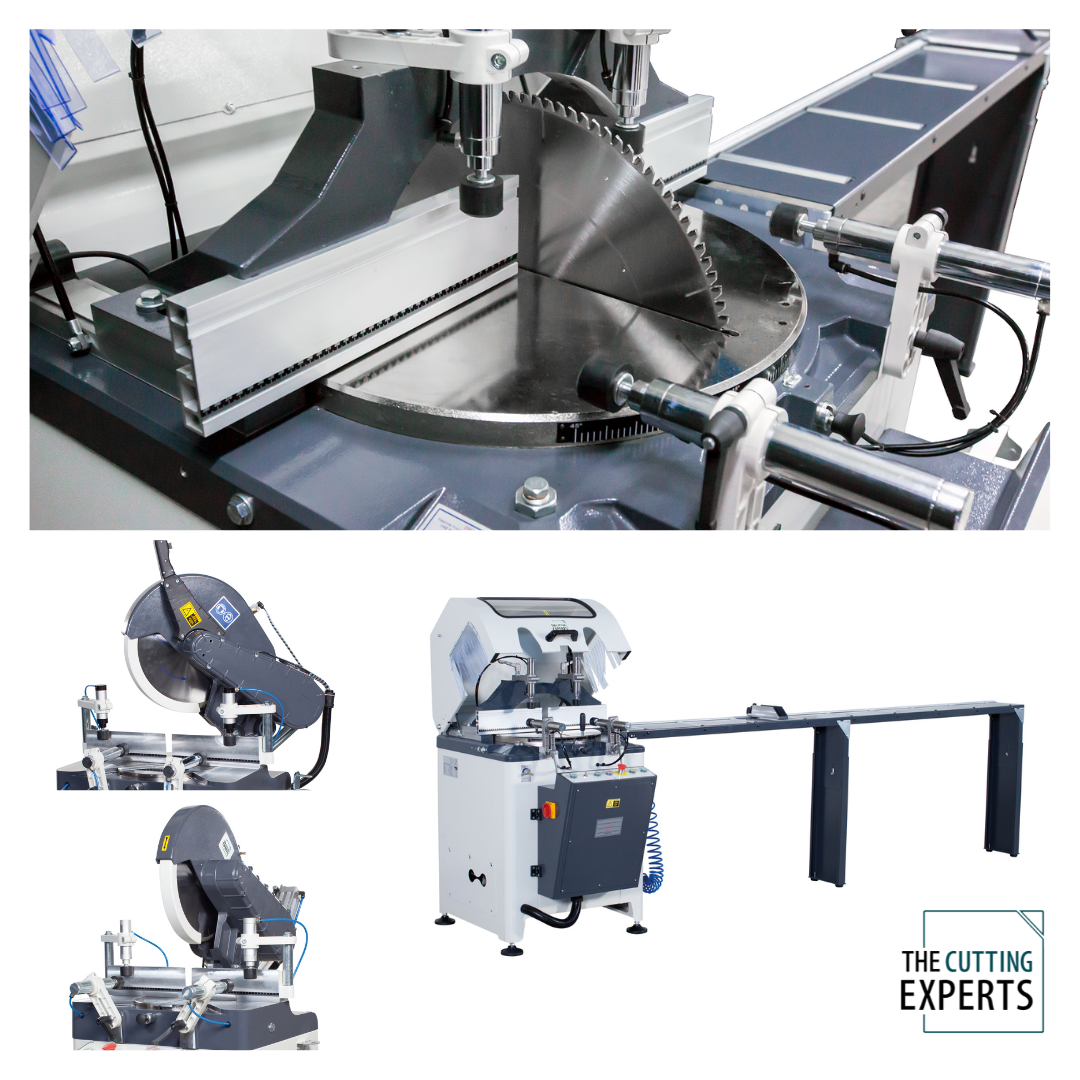

The Shark Series of Industrial Miter Saws

At The Cutting Experts, we offer a wide range of industrial miter saws to meet your needs. One of our most popular products is the Shark series of upcut saws. These saws are heavy-duty machines that are designed for industrial usage. They are suitable for a variety of applications, including cutting aluminum, PVC, and wood profiles.

The Shark series of upcut saws comes with a variety of features that make them ideal tools for cutting miter. For example, they come equipped with a rotating table that rides on roller bearings, which allows for precise cuts. They also have a solid cast iron base, which provides stability and helps to reduce vibrations during cutting.

Additionally, the Shark series of upcut saws comes with a variety of blade options, including blades with diameters of up to 24 inches. This means that these machines have a high cutting capacity, which is essential in industries where large pieces of material need to be cut.

Benefits of Using Industrial Miter Saws

A. Precision cutting: Industrial miter saws are designed for precision cutting and are capable of making angled cuts with a high degree of accuracy. This makes them an ideal tool for jobs that require precision and attention to detail.

B. Multi-purpose capabilities: Many industrial miter saws are designed to be multi-purpose machines suitable for a wide range of cutting tasks. They can be used to make compound miter cuts, straight cuts, and cross cuts.

C. Cutting capacity: Industrial miter saws are capable of cutting through a variety of materials, including wood, plastic, and aluminum. The cutting capacity of an industrial miter saw is determined by the blade diameter and the size of the table.

D. Durability: Industrial miter saws are built for heavy-duty industrial usage and are designed to withstand the rigors of daily use. They are typically made from high-quality materials and feature solid cast-iron bases and rotating table rides for maximum stability.

E. Speed and efficiency: Industrial miter saws are designed for speed and efficiency, allowing operators to make accurate cuts quickly and easily. This makes them an ideal tool for high-volume cutting tasks.

F. Increased productivity: The precision and speed of industrial miter saws make them an excellent tool for increasing productivity. With an industrial miter saw, operators can make accurate cuts quickly, allowing them to complete jobs faster and more efficiently.

Common Applications of Industrial Miter Saws

Industrial miter saws have a wide range of applications in various industries. Here are some of the most common applications of industrial miter saws:

Cutting various materials such as wood, plastic, and aluminum: Industrial miter saws have versatility in terms of material cutting as they are able to cut through various materials including wood, plastic, and extruded aluminum. These tools are applicable in numerous industries such as construction, woodworking, and manufacturing.

General carpentry: Industrial miter saws are perfect for making precise angled cuts in wood for general carpentry work. They can be used for cutting lumber for framing, baseboards, crown molding, and other types of decorative trims.

Cutting moulding and trim work: Industrial miter saws are widely used in the woodworking industry for cutting intricate moulding and trim work. They can make precise compound cuts, bevels, and angles that are required for different types of moulding and trim work.

Cutting pipe and metal: Industrial miter saws can also be used to cut pipes and metal. They are ideal for cutting metal tubes and pipes used in plumbing, electrical work, and other metalworking applications.

Overall, industrial miter saws are essential tools for any industry that requires precise angled cuts. Their versatility and accuracy make them valuable assets for many professionals.

Conclusion

Industrial miter saws are an important tool for many industries that require precision cutting and multi-purpose capabilities. With their durability, cutting capacity, and speed, they are a valuable addition to any workspace. The Shark series of industrial miter saws offered by The Cutting Experts is a reliable and efficient option for those in need of heavy-duty saws. The features and specifications of the Shark series, such as the rotating table, double miter, and roller bearings, make it an ideal tool for cutting various materials with accurate cuts and maximum smoothness. We highly recommend purchasing industrial miter saws for any business that requires efficient and precise cutting capabilities. And when looking for an industrial miter saw, be sure to check out The Cutting Experts and their selection of high-quality saws, including the Shark series.